Winnerjet A2 60CM DTF Printer With i3200 Printhead & Powder Shaker

With stable performance and perfect function, I3200 DTF Printer is designed with unique appearances including blaze, edge, and cube, helping to catch help you capture the customer’s psyche in the first place.

Technical Highlights:

Print Head: 2/4/8 Epson I3200 print heads.

Print Size: 24″(60CM) Print Width.

Print Speed: 3.5-22m2/h

Ink Type: CMYK+W/CMYK+Fluorescent Colors+W/CMYK+CMYK+W

Warranty: 24 months (Ink system, printheads and ink capping are not covered)

International Shipping: DHL,FedEx,By Air,By Sea

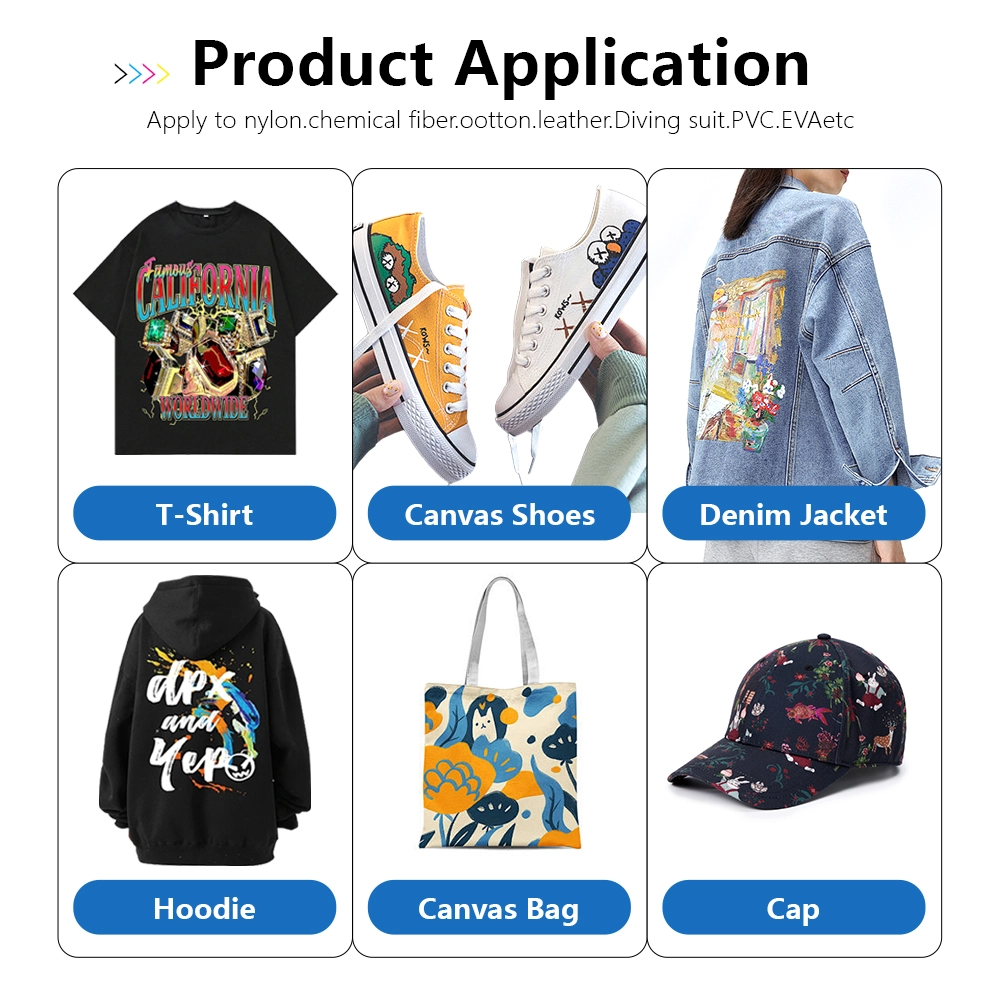

DTF Printer Selling Point

Newly Upgraded, High Efficiency And Durability

Nozzle humidification

It has its own nozzle moisturizing system, which automatically replenishes special water to the nozzle when the machine is not running for a long time, to achieve a moisturizing effect and prevent the nozzle from being blocked.

Low Temperature Protection

The heat consumption of ink during the conduction process is replenished throughout the process to maintain the fluidity of ink, avoid cooling and precipitation, and reduce the probability of nozzle clogging.

Smart Curing

According to the fluidity of the ink, the curing temperature and time are automatically adjusted to ensure the adhesion between the powder and the fabric and enhance the firmness of the pattern.

Multiple Print Heads

Multiple printheads can be supported to improve printing accuracy and efficiency. The quality of printed patterns will be higher, making them suitable for enterprises to carry out mass production.

Ink Recycling System

Adopt a modified ink special continuous supply system, which can store more ink at one time, save the time of replacing the ink, and improve work efficiency. At the same time, non-stop printing can prevent ink from settling and printing better.

Latest Paper Feeding System

Updated from a single send film, receive film to adjustable clamping stick and paper stick, can use the roll of film mass production, can also print a single film customized, more flexible, more adaptable to changes in market demand.

Automatic Powder Shaker

With an automatic powder shaking system, you can evenly spread the hot melt adhesive powder on the transfer film and then shake off the excess powder to ensure even coverage meanwhile with a powder recycling system to reduce waste and secondary use.

Intelligent Curing Oven

The curing temperature can be adjusted according to the actual printing effect, which can completely cure the hot melt powder on the surface of the transfer film and ensure the durability of the printed pattern.

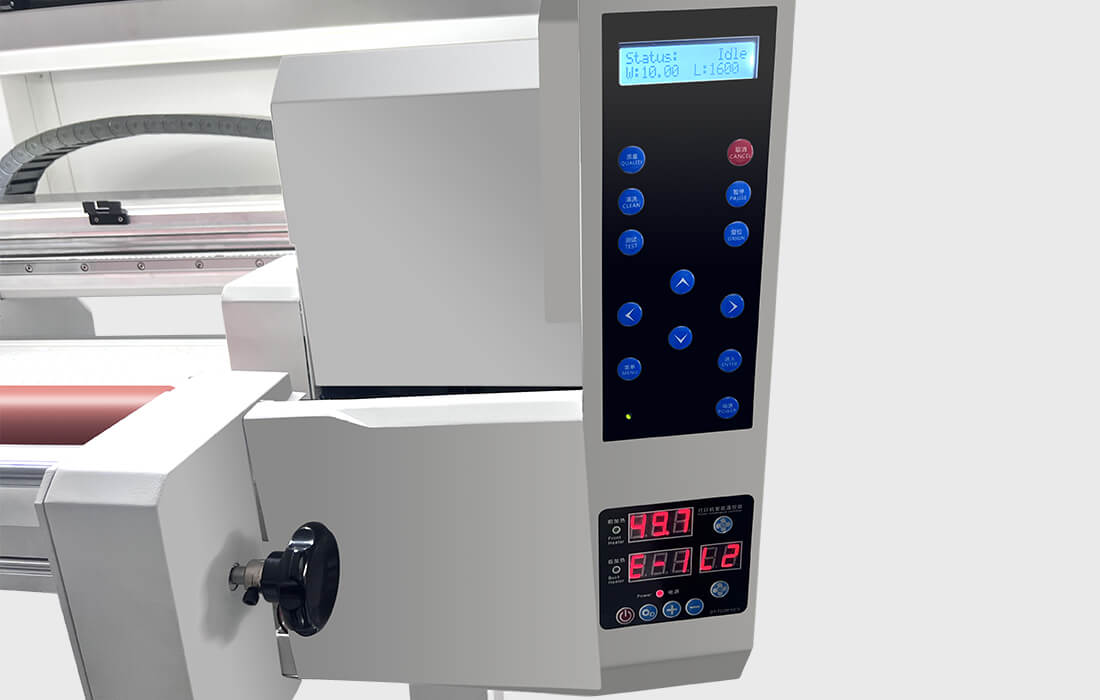

DTF Printer Operation Interface

The interface is simple, multi-functional, and easy to operate. The operating manual is user-friendly and can be used quickly by both experienced technicians and novices.

The New Version Of The Bracket

Size marking and print film fixing devices ensure that the print size is correct, the transfer film does not deviate from the print track, and the position of the print pattern is correctly aligned with the transfer film.

Epson I3200-A2 Print Head

Winnerjet A2 series DTF printers can be equipped with 2/3/4/8 Epson I3200 print heads. The printing accuracy is high, the efficiency is high, and the resolution is high. Together with the machine’s unique print head compensation function, it can ensure high color saturation and clear details.

| Model | I3200-A2 |

|---|---|

| Ink Types | Water based ink |

| Size(width x depth x height)(mm) | 69.1×59.4×35.6 |

| Weight(g) | 82 |

| Nozzle Numbers | 3200 |

| Length Between Nozzles(inch) | 1/300(in one row) |

| Nozzle Row | 8 row |

| Max color/head | 4 colors |

| Resolution | 300 npi/1 row 600 npi/2 rows |

| Effective Printing Width(mm) | 33.8 |

| Jet Freqency(kHz) | 43.2 (single dot), 21.6 (multi dot) |

| Ink Drops(pl) | 3.8-6-12(9.4) |

| Ink Viscosity(mPa.s) | 3~4 |

| I3200 DTF PET Film Inkjet Printer | ||||

|---|---|---|---|---|

| Brand | Winnerjet | |||

| Item Model | DTF-I3200-2 | DTF-I3200-4 | DTF-I3200-8 | |

| Print Head | Using Epson print head, including 400 nozzles/row*8*lines, high quality up to 1800dpi | |||

| Print Resolution/Speed | 4pass: 12m2 /hour | 4pass: 22m2 /hour | ||

| 6pass: 8m2/hour | 6pass: 16m2 /hour | |||

| 8pass: 6m2/hour | 8pass: 12m2 /hour | |||

| Ink | Types | Pigment Ink(C,M,Y,BK+W) | Pigment Ink(C,M,Y,BK+Fluorescent Colors+W) | Pigment Ink(C,M,Y,BK+W) |

| Capacity | 5 Colors: 1.5L*5/color | 9 Colors: 1.5L*9/color | 5 Colors: 1.5L*5/color | |

| Media | Maximum Width | 620mm | ||

| Thickness | 1.5mm to 6mm adjustable | |||

| Max Roll Weight | 20kg | |||

| Types | PP Synthetic Paper, Vinyl Sheet, Film, Coated Paper, Canvas , Adhesive Vinyl Sheet, Banner and so on. | |||

| Media Heater | Front/Mid/Rear Heaters (individually controllable) | |||

| Interface | Network Port | |||

| RIP Software | Maintop6.1, Photoprint, Print Factory | |||

| Power Supply | AC110V+/- 10%, AC220V+/-10%, 50/60+/HZ | |||

| Power | 200w~450w | |||

| Operating Environment | Temperature: 20℃- 35℃, Humidity: 35%RH-65%RH | |||

| Dimensions | 1766*750*1513mm (L*W*H) | 1766*750*1513mm (L*W*H) | ||

| Height of Worktable | 1062mm | 1062mm | ||

| Package size | 1880*1060*740mm (L*W*H) | 1880*1060*740mm (L*W*H) | ||

| Net Weight | 190KG | |||

| Gross Weight | 210KG | |||

Automatic Powder Shaking

| DTF Powder Shaker And Dryer | ||||

|---|---|---|---|---|

| Model | DTF-3200 (S08) | |||

| Operation mode: | PLC Touch Screen | |||

| Max Width: | 600 mm | |||

| Oven Length: | 1079 mm | |||

| Oven Temp.: | 0-400°C (be adjustbale) | |||

| Voltage: | 110v / 220v, 3phase, 60Hz | |||

| Power: | 3.5 KW | |||

| Shaker Size: | 1850mm (L) x 97mm (W) x 90mm (H) | |||

| Shaker Weight: | 300kg | |||

Print Design

Import the prepared design into the printing software, adjust the printer settings, and start printing.

Cure Design

Fully automatic process: after shaking the powder, it automatically enters the curing oven, and the film is collected after curing is completed.

Transfer Design

Heat the hot press to 180-220℃ degrees with medium pressure and press for 15-30 seconds to complete the transfer.

Complete design

After waiting for the transfer film to cool down, carefully peel off the film from one corner to complete the design.

Buy a Winnerjet DTF printer online and get a free premium DTF printing starter kit.

The Starter Consumables Set includes:

- DTF Film: 60CM*100M/30CM*100m 1 Roll

- DTF Powder: 2 kg (4.4 lbs)

- DTF Ink: 1000ml*5 (c,m,y,k+w)

- Rip Software: Flexi Print/Maintop

- Winnerjet DTF Environment Settings

- Winnerjet DTF Instructional Video

Q: What Is A DTF Printer And How Does It Work?

A: DTF printers are specialised machines for textile printing and are usually used in conjunction with DTF Ink, DTF Film and DTF Powder.

Q: What Kind Of Printer Do I Need For DTF Transfers?

Determine the right DTF printer to choose based on your customer’s needs and budget money.

Q: What Is DTF Printing And How Does It Work?

It is a type of printing method where the usual steps are Preparation of the design – Printing of the design – Curing of the design – Transferring of the design – Completion of the design.

Q: What Is DTF Ink And How To Use It?

Specialised inks for DTF printers, the high quality of the ink ensures vibrant colours in the print pattern.

Q: What Is DTF Pet Film?

A special film used to print and transfer designs, which serves to take up the design.