DTF Powder - OEM/ODM Bulk Order

Hot Melt Powder Wholesale | Factory Direct Supply

Suitable for all DTF printers | Strong viscosity

Environmental certification | OEM customization

🚛 3-5 days fast delivery

🌿 Environmental certification (OEKO-TEX | RoHS | MSDS)

⚡ High adhesion & soft feel

📦 1kg minimum order, support OEM/ODM

DTF Powder

🚛 3-5 days fast delivery

🌿 Certification (OEKO-TEX | RoHS)

⚡ High adhesion & soft feel

📦 1kg MOQ order, support OEM/ODM

Hot-Selling Models

Our Hot Melt Adhesive Powder Collection

500G DTF Powder

(500G/Bag White)

1000G DTF Powder

(1000G/Bag White)

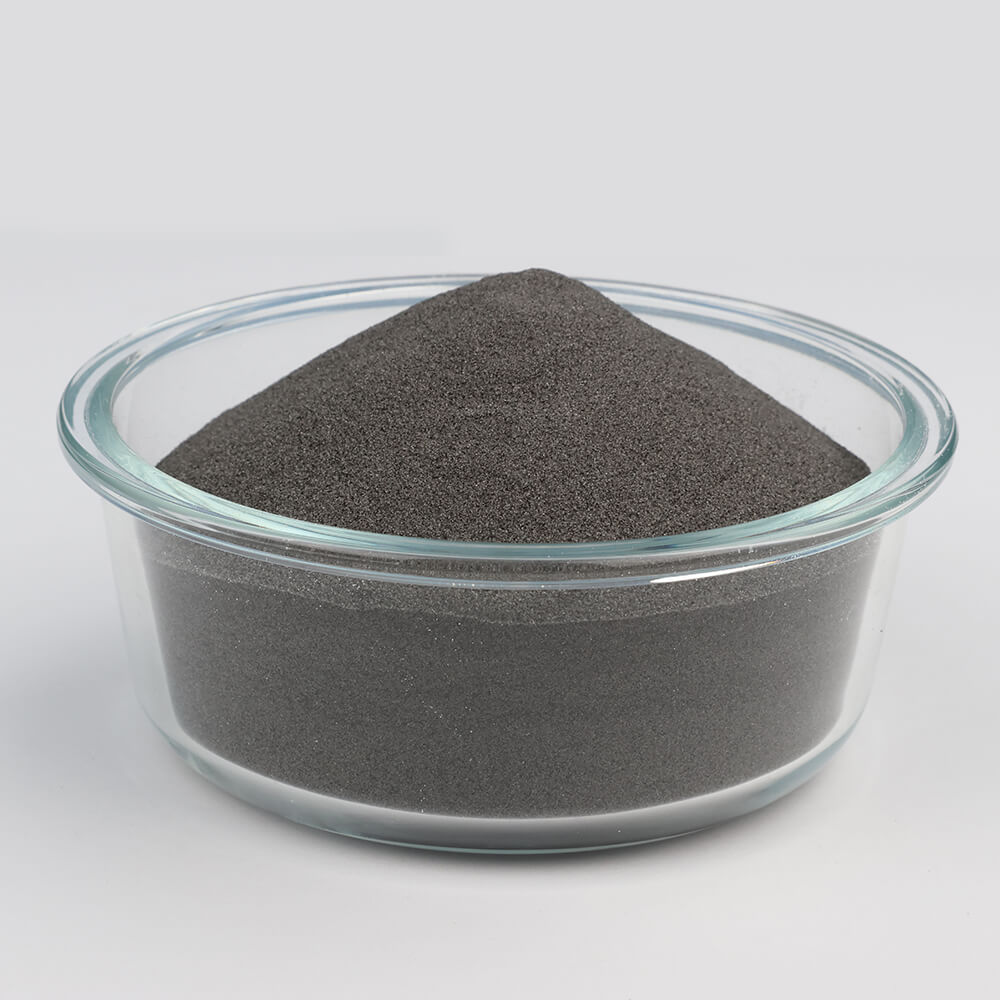

Black DTF Powder

(500G/Bag)

1KG DTF Powder

(1000G/Bag)

Why Choose Winnerjet DTF Powder Manufacturer?

Our DTF Powder Factory

Winnerjet, as a DTF powder manufacturer, specializes in producing high-quality hot melt powder for garment printing, ensuring strong adhesion, soft touch, and good washability. As a leading factory, we provide bulk supply, OEM service, and fast turnaround to meet the needs of distributors and manufacturers. With strict quality control and advanced production lines, we guarantee consistent performance and competitive prices. Cooperate with Winnerjet to improve your DTF printing efficiency and market competitiveness!

Winnerjet vs. Other Providers

| Comparison | Winnejet | Other Company |

|---|---|---|

| Adhesion | 50+ washes without falling off | Ordinary DTF Powder is easy to fall off |

| Environmental Friendly | ECO-Passport & Oeko-Tex® Certified certification | No certificate, does not meet the export standards of the European and American markets |

| Supply Ability | Factory direct delivery, stable supply | Unstable supply, slow delivery |

| Brand Design | OEM customization support | Unable to provide OEM service |

| Deliver | Global delivery, worry-free logistics | Uncertain delivery |

FAQS

What DTF models are your DTF Powder suitable for?

Compatible with all brands of DTF printers, including Epson, Ricoh, Brother, Mutoh, Roland and domestic models.

How do you choose the size of powder particles?

Different particles are suitable for different needs:

Coarse powder (easy to peel, good air permeability)

Medium powder (standard printing, suitable for most applications)

Fine powder (high-precision pattern, soft feel)

Is your DTF Powder environmentally certified?

OEKO-TEX / RoHS / MSDS certified, in line with European and American environmental standards.

Do you provide OEM/ODM customized services?

Yes, we support brand customization, packaging customization, and specification customization!

What is the delivery time & minimum order quantity?

Small batch (1-50kg): 1-3 days delivery from stock

Bulk order (100kg+): 5-7 days delivery

Trustworthy DTF Powder Supplier