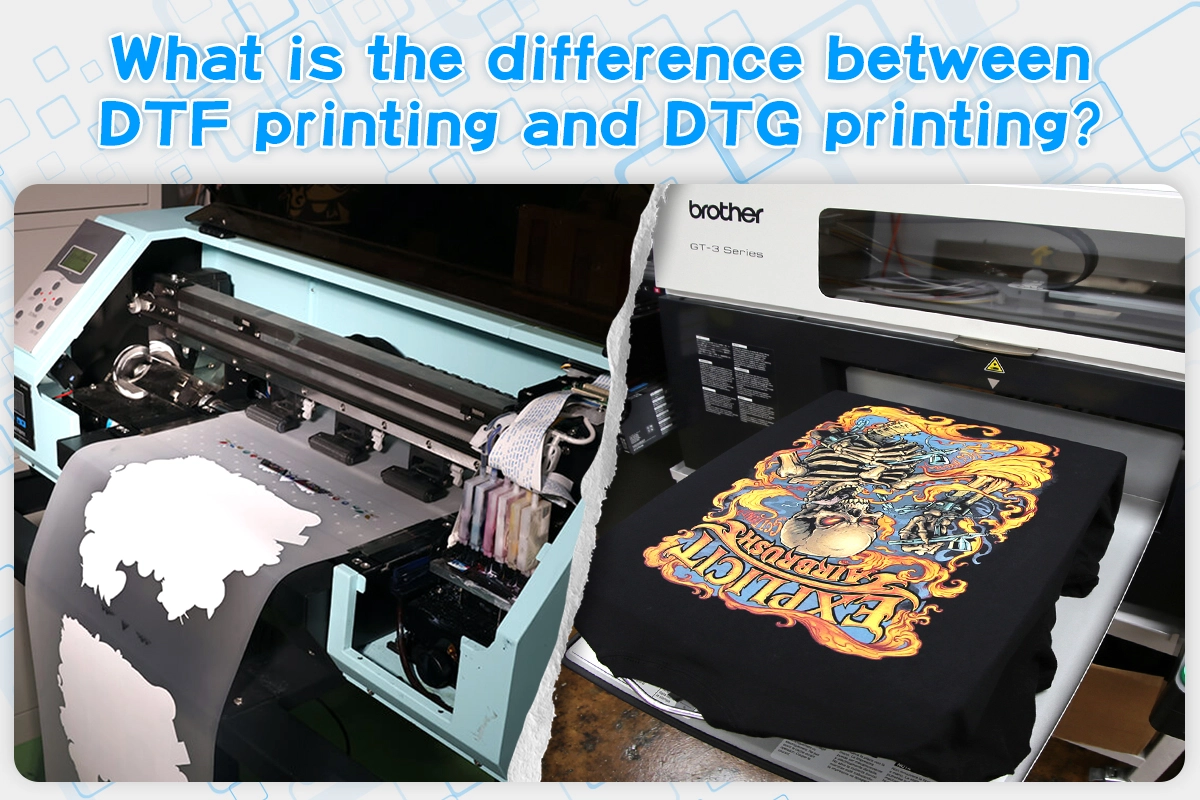

DTF and DTG look similar, but they are very different.Both DTF (direct-to-film) and DTG (direct-to-garment) printing are popular methods for custom apparel printing. Both have unique advantages and applications.

Read on to learn about their differences and find the best option for your business needs.

What is DTF printing?

DTF printing, or Direct-to-Film printing, is a relatively new method that involves printing designs onto a special film. This film is then transferred onto the fabric using heat and pressure. The process includes printing with specialized inks that adhere well to various materials. DTF printing is known for its versatility and ability to produce vibrant, detailed designs that can be applied to a wide range of fabrics.

What is DTG printing?

DTG printing, or Direct-to-government printing, is a more established technique that allows ink to be directly printed onto the fabric of the garment. This method uses specialized inkjet technology to apply water-based inks directly onto the fabric, allowing for high-resolution images with a soft feel. DTG is particularly favored for its ability to handle intricate designs and color blends, making it ideal for custom apparel and small runs.

What is the Difference between DTF and DTG?

Applicable fabrics

DTF printing works on almost all fabrics, including cotton, silk, nylon, polyester, leather, blends, and more. Flexible fabric compatibility means you can use DTF for a wider range of your business.

In contrast, DTG printing is mainly suitable for 100% cotton fabrics. Although DTG is making progress in the application of synthetic fabrics, the best results are still seen in cotton garments.

Print Quality

DTF printing can produce vibrant colors and sharp details with great image reproduction, especially on darker fabrics, making it a strong contender for bold designs.

DTG printing generally provides a softer effect as the fabric absorbs the ink. This is particularly attractive for designs with subtle gradients or detailed images.

Durability

DTF prints are generally more durable than DTG prints because the adhesive used in the transfer process helps the pattern to bond more firmly to the fabric. DTF prints have been tested to last over 60 washes without noticeable fading.

DTG prints are also durable but can fade or crack over time if not properly cared for, especially if the garment is not properly washed.

Touch Feel

DTF printing is to transfer the pattern to the fabric, which exists on the surface of the fabric, so it feels like a layer.

DTG printing is to form a pattern by directly fusing the ink with the fabric fibers, which exist inside the fabric, so it feels very soft.

Application market

DTF printing can be used in a variety of markets, including custom clothing, shoes, handbags, backpacks, masks, and even home textile printing. Its versatility enables companies to meet a wide range of customer needs.

DTG printing is mainly used for custom clothing, suitable for personal DIY customization and small-batch customization of enterprises.

Order volume

If you are a business that produces large batches of orders, DTF is a better choice because it does not require pre-processing. Winnerjet’s DTF printer provides printing process automation and is more efficient in processing batch orders.

DTG printing is more suitable for small batch production and requires detailed custom design because each print requires pre-processing and requires more setup time.

Environmental protection

DTF production can reduce waste, such as DFT powder recycling, making it ideal for sustainable use.

DTG printing usually uses water-based inks, which are less harmful to the environment than some DTF inks (which contain chemicals).

Investment

DTF printers are more affordable than DTG printers, making them a more acceptable option for small businesses or startups. However, when printing with DTF, the ongoing costs of supporting consumables such as DTF inks, DTF films, and DTF powders must be considered.

The initial cost of a DTG printer is relatively expensive, which is stressful for individuals and startups, and the subsequent benefits are higher.

DTF and DTG, which one is more suitable for me?

To sum up, if you are doing large-volume orders on a variety of fabrics, DTF is your best choice. If you often customize cotton garments, DTG is your ideal choice. When making a decision, please consider factors such as your order volume, budget, and the type of designs you hope to create.

FAQs

Q: which is better DTG printing or DTF printing?

A: If you mainly print on cotton garments, pay attention to details and soft feel, and choose DTG printing. If you need to print on different fabrics and do large-scale production, choose DTF printing.

Q: Is DTG printing suitable for large batches?

A: Although DTG can be used for large batches, small batches are usually more efficient due to print setup.

Q: Which method is more cost-effective, DTF or DTG printing?

A: DTF printing has lower initial equipment costs, but ongoing costs will depend on your consumables usage.

Q: How long can DTF and DTG prints last?

A: DTF prints can last for years if properly cared for and cleaned, and DTG prints are also long-lasting.

Q: Can I print white ink with DTF and DTG?

A: Yes, both methods support white ink printing. DTF is particularly suitable for printing white patterns on dark fabrics, while DTG usually requires pre-treatment to achieve the best results when printing white ink.